Our History

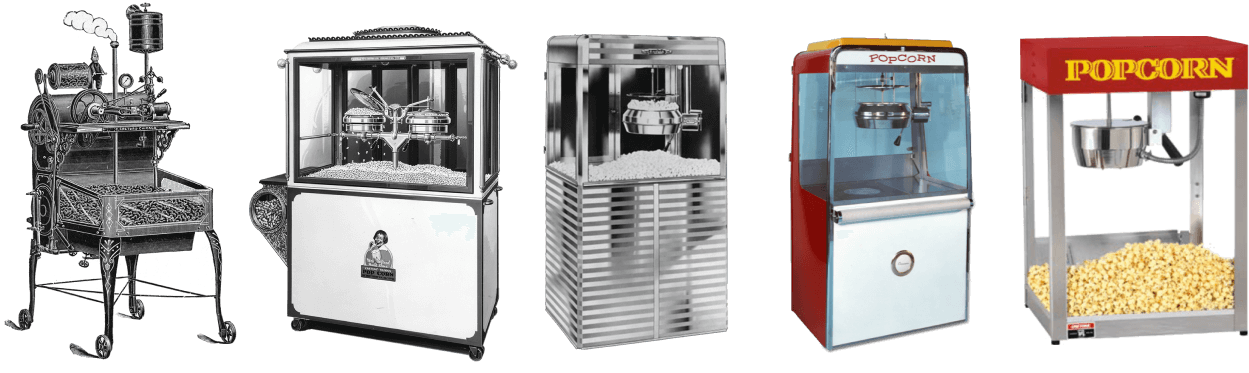

An Age of Invention

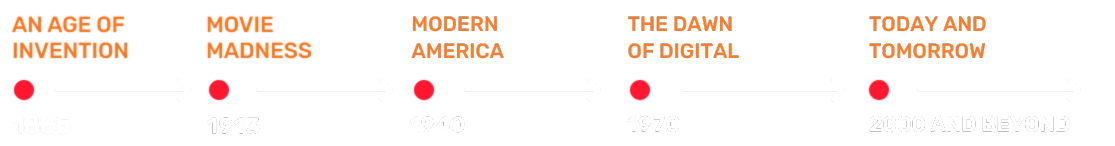

1885-1912

Charles Cretors’ imagination led to an invention, the first commercial popcorn machine. That invention brought innovations that led to an industry. An era of invention on the coattails of the Industrial Age ushered in the Cretors’ steam powered popcorn popper and peanut roaster introduced at the World’s Fair of 1893. The Wright Brothers first flight, Henry Ford’s Model T, the advent of electricity – C. Cretors & Company was in good company in its first decades. Next came more poppers, wagons and the first counter models, as well as popcorn oil for a better taste. Skilled engineering labor helped set Cretors apart as the company trusted for quality.

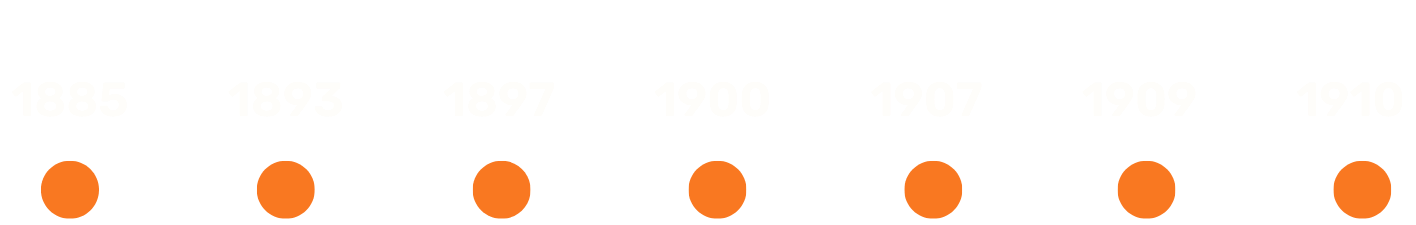

1885

Charles Cretors, an Ohio-born craftsman, brought his inventive spirit to Chicago in the 1880s. There, he designed a revolutionary steam-powered peanut roaster that provided consistent results and reliable operation. To capture attention, he added a steam-powered clown, the Tosty Rosty Man, who stirred peanuts in a glass tumbler.On December 2, 1885, Charles secured a peddler’s license and placed his machine on the sidewalk in front of his shop. It roasted snacks, turned heads, and marked the official beginning of C. Cretors and Company.

With the help of J.M. Savage, a traveling salesman who became the company's first official sales representative, word spread quickly. What began as one man’s inventive spirit sparked a new industry—and laid the foundation for a company that has thrived across three centuries of innovation, craftsmanship, and concession excellence.

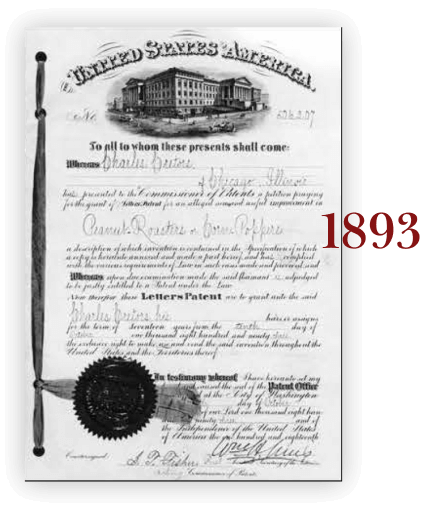

1893

1893 marked a turning point in the appeal of popcorn over peanuts among the public. Charles Cretors upgraded his No. 6 peanut roaster by adding a built-in popcorn popper—transforming how popcorn was made. Unlike traditional methods by popping corn in a basket over an open flame, his steam-powered machine automatically stirred popped corn evenly in a kettle and seasoned with a mix of butter and seasonings. His method delivered consistent, high-quality results—marking the creation of the world’s first modern popcorn machineCretors applied for a patent in 1891 for his corn popper and peanut roaster, which was officially granted in 1893. This was also the same year of The Columbian Exposition situated on Chicago’s lakefront. The World’s Fair welcomed millions of visitors and showcased exhibits from countries around the world. It was a celebration of American innovation—and the perfect stage for Charles Cretors to debut his revolutionary steam-powered popcorn machine on the Midway Plaisance. That moment marked the beginning of C. Cretors & Company’s long—and still growing—legacy in the concession industry.

1897

By 1897, C. Cretors & Company had expanded its product line to include tall, upright machines that were built with mobility in mind. Large rear wheels made it easy for store owners to roll the units outside during the day to attract foot traffic, then back inside at night for safekeeping. Wagons followed—and quickly became a trendsetter. Hand-pulled and horse-drawn popcorn wagons gave operators the freedom to take their business to the crowds. These wagons evolved into early mobile concession stands, perfect for state fairs, parks, and busy public spaces.In a sign of growing international interest, Cretors exported its first machine abroad in 1897: a Model No.1 Wagon sold to the Netherlands’ Gist and Spiritus Fabriek in Delft for $400. It is still owned and on display at the successor company, Unilever.

1900

C. Cretors and Company moves to 620 W. Cermak Road in Chicago—a location the company proudly called home for the next 76 years. This historic address became the backdrop for decades of innovation, craftsmanship, and growth.

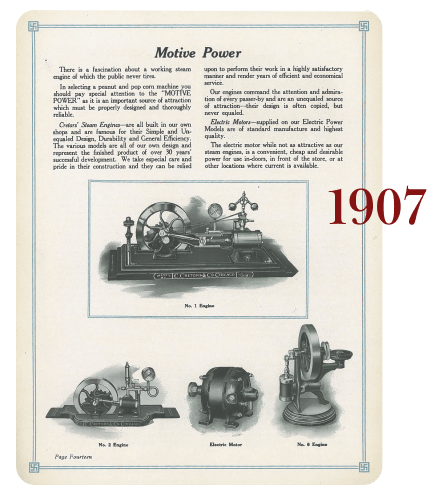

1907

As the 20th century approached, electricity began reshaping American life. Electric motors became widely used in indoor environments, offering a cleaner, quieter, and more efficient alternative to steam power, which was often seen as complex and potentially risky. As retail businesses moved indoors, the demand for electric-powered equipment grew.Charles Cretors recognized this shift and responded with electric machines designed for performance, reliability, and profitability. In 1907, Charles and his son, Hazael DeWitt, received a patent for converting steam-powered equipment to run on an electric motor.

That same year, the company introduced its first No. 3 peanut roaster and corn popper powered by electricity, marking a significant step forward in concession equipment and reinforcing Cretors’ reputation for innovation.

1909

After a decade of development, Cretors revolutionized the concession industry once again with the introduction of the first self-propelled Peanut and Popcorn Wagon—powered by a four-cylinder Buda gasoline engine. This innovation marked a pivotal shift from horse-drawn wagons to gasoline-powered mobility.The Buda engine, widely favored by early truck manufacturers, allowed Cretors to design larger wagons with greater range and flexibility. Outfitted to sell popcorn, peanuts, candy, and soda, these vehicles weren’t just eye-catching—they were the very first mobile concession stands ever known.

Later models, known as Automobile Wagons, were built on Model T and Model AA Ford chassis, blending style with function.

In 1909, Mrs. L.P. Dupoyster of Cairo, Illinois, made history as the first buyer of a Cretors automobile model, purchasing it for $1,850. Her investment helped usher in a new era of mobile snacking and on-the-go indulgence—an idea that would inspire generations to come.

1910

With the introduction of the first electrically powered Model 3 Peanut Roaster and Corn Popper, Cretors marked another industry first—this time in electrical safety and innovation. The machine earned the company its first UL certification, file number E4175, which remains active to this day. The application of the electric motor was soon added to other machine models as electric power replaced steam power.C. Cretors & Co. holds one of the oldest active Underwriters Laboratories (UL) certifications ever issued for a machine powered by an electric motor—a lasting testament to the company’s commitment to quality, safety, and forward-thinking design.

1913-1939

Movie Madness

1913-1939

Charles Cretors patented a popper powered by electricity before it was a commonplace convenience, let alone a necessity. It would help secure Cretors’ position in early movie theaters popping up across the American landscape. A complete line of supplies followed: corn, seasoning, boxes and bags as well as critical safety features. With the advent of talkies, movie concessions moved indoors. As the Great Depression ravaged the global economy, movies provided a much-needed escape. Increased attendance provided extra concession profits from popcorn machines and helped theaters stay in business. Cretors continued to lead the way. Hazael D. Cretors, son of Charles, became president in 1934 and revolutionized the company’s marketing materials during the heyday of catalog shopping. He helped tell and sell Cretors, while keeping the company afloat through the Great Depression. Bookended by two World Wars, this was an era of great change in America, and a time of continued innovation and leadership by Cretors.

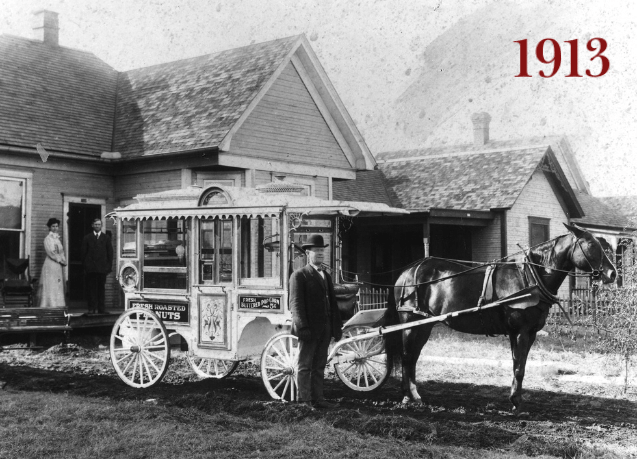

1913

Expanded wagon models included horse drawn as well as pull carts. Many street vendors were able to make enough profit using their machine to purchase a house for the first time.

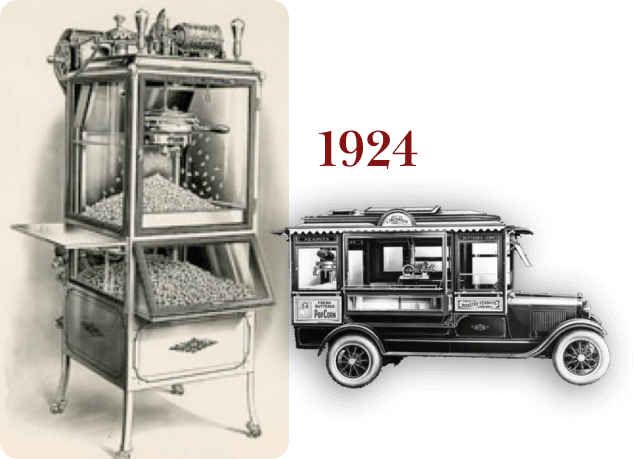

1924

The Earn More model is introduced, making it the first machine that could be used both indoors and out. Over its more than 25 years in the marketplace, it was the most successful machine that the company ever produced. Expanded wagon models include a Model D wagon mounted on a Ford Model T Truck chassis and an automobile popcorn machine using a Ford Model A Truck.

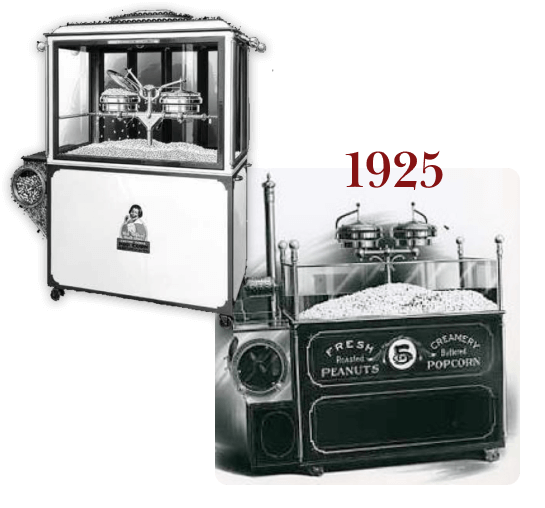

1925

To meet the growing crowds at theaters, recreation areas, and ballparks, Cretors introduced high-volume machines featuring double poppers. As electric models gained popularity, steam-powered machines and wagon sales began to decline. Retailers were also transitioning from street vending to indoor storefronts. In response to these changes, Cretors unveiled more than nine new popcorn machine models, each designed to meet the unique demands of this evolving market.

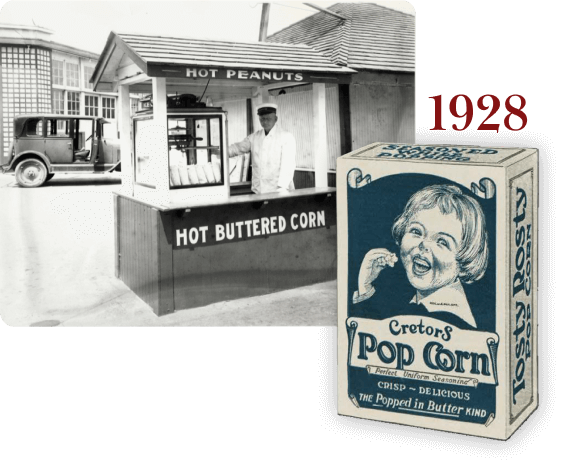

1928

Booster Boy is created as a trademark and used in advertising to sell Cretors’ line of supplies, which include corn, seasoning, cartons and bags. “Boost your profits with Cretors Supplies!” would become a successful advertising slogan.

1934

Candy Coated Popcorn equipment is introduced. A first of its kind, the Duplex gave the user the ability to pop and candy coat popcorn in one machine. The first caramel corn shops were born.

1938

As movie theater operators began to recognize the impressive profit margins associated with popcorn sales, they started viewing popcorn machines as essential profit centers rather than mere novelties. Concession sales—particularly popcorn and ice cream—proved instrumental in offsetting theater operating costs. In response to this growing demand, Cretors introduced the Hollywood Machine, specifically designed to meet the needs of the expanding theater market.1931-1950

Modern America

1940-1969

The early 1940s brought big changes as America entered World War II. Under the War Production Board's L-65 order, Cretors shifted from making popcorn machines to producing aircraft oil line fittings, radio components, and jack floats for anti-aircraft guns. Led by new president Charles J. Cretors, the company proudly supported the war effort.

After the war, the rise of television challenged movie theaters, but innovations like drive-ins and color films kept audiences returning. Cretors adapted once again, expanding into new markets, launching new designs, and opening a sales office in Nashville. In 1967, the company introduced its patented Flo-Thru® system, a breakthrough in high-volume popcorn production using continuous hot-air technology.

1946

After World War II, Cretors’ regular manufacturing work resumes. The steel shortage requires Cretors to temporarily use wood instead of steel to build the popper cabinets for the Super 60 Machine.

1948

At the request and under the guidance of the Popcorn Processor Association, Cretors develops the Official Weight Volume Tester (OVT), a laboratory machine that becomes the industry standard for measuring how much popcorn expands when popped—used by breeders, manufacturers, and researchers to identify the highest-yielding and best-performing hybrids.

1953

Cretors’ first national sales office is established in Nashville, TN.

1954

Raymond Loewy, an award-winning industrial designer known for his innovative and sleek designs, was enlisted by Cretors to bring a fresh and modern aesthetic to the traditional popcorn machine. Tasked with creating an attractive and functional machine for movie theaters, Loewy’s design for the Ambassador popcorn machine was a perfect blend of form and function. His sleek, modern styling caught the eye of theater owners across the country, establishing the Ambassador as an iconic and timeless piece of equipment. It remains the hallmark of the Cretors line for well over a decade.

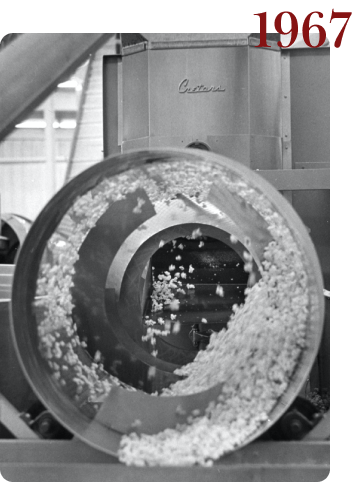

1967

In response to growing demand for industrial-scale snack food processing, Charles D. Cretors, fourth generation company president designs and patents Flo-Thru technology, creating the first industrial hot air popcorn machine. 50+ years later, these machines are able to pop up to 5,000 lbs. (2,267 KG) per hour.1970-1999

The Dawn of Digital

1970-1999

While the Counterculture challenged social structures, Cretors company culture remained committed to engineering excellence and smart business, even as the world economic and political landscapes changed. The Berlin Wall fell, followed soon after by the entire Soviet Union. The Internet was born, fundamentally changing society, the economy and the ways business did business.

Under Charles D. Cretors, who becomes president in 1974, focus continues on the Flo-Thru® business and on features and options to improve concessions machines, like the Bag-In-Box oil pump and larger kettle sizes. The company moves to North Racine Avenue and then to North California Avenue and relocates the sales department from Nashville to Chicago. In less than a decade multiplexes booms and slows. And through it all, Cretors persevered.

1974

The Metric Weight Volume Tester (MWVT) replaces the OVT in response to changing popcorn hybrids. It soon becomes the only standard testing machine used by the Popcorn Institute.

1976

The T-2000 marked the beginning of the Red Top line—a smaller, more compact series of poppers designed to meet the needs of operators with limited space. With its efficient footprint and dependable performance, the Red Top line extended Cretors’ reach into concession stands, convenience stores, and other non-theater venues, opening the door to new markets.

1978

Expanding into new markets led to the development of several innovative products including cotton candy. The Perfection Cotton Candy Floss Machine was introduced as a reliable and efficient solution for cotton candy production. Building on its success, it evolved into the Ringmaster Cotton Candy Machine, a popular addition to the Cretors product line

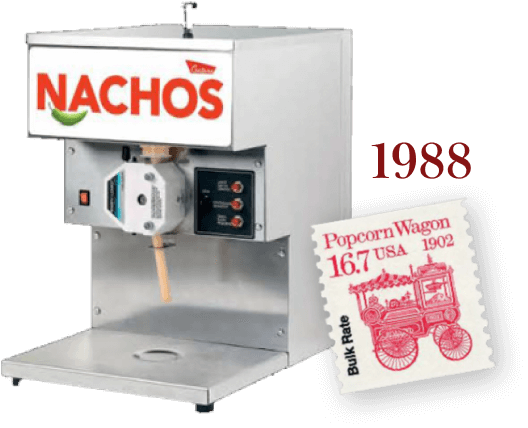

1988

The United States Postal Service honored Cretors’ legacy by featuring an illustration of the 1902 Model No. 1 Wagon on a postage stamp. Issued as part of the Transportation Series, the stamp paid tribute to America's early snack food wagons and their role in shaping the nation's culinary culture.In response to growing demand in the new industries, Cretors expandes its product line to include Nacho Equipment—introducing a patented Nacho Cheese Pump and a range of Nacho Chip Warmers designed to meet the needs of emerging snack trends and evolving customer preferences.

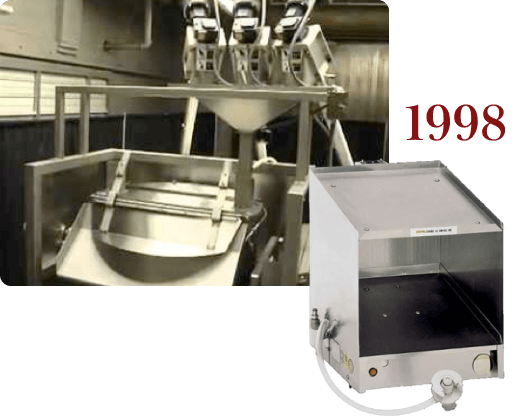

1998

Cretors’ ability to anticipate customer needs led to the Bag-in-Box (BIB) oil pump—an efficient, mess-free alternative to heavy oil pails. Inspired by soda syrup systems, it sparked a full line of oil pumps now standard in popcorn machines. Innovations followed, including the BIB Butter Topper Dispenser, and the BIB Backroom Warmer.The G-Zilla popper is developed and added to the Cretors Industrial product line as a high-capacity wet-popping kettle, capable of producing up to 250 pounds (113 kg) of popcorn per hour—one of the largest in the industry. Designed for high-volume snack food production, the G-Zilla delivers exceptional efficiency and output for large-scale operations.

2000, Today & Tomorrow

Into the 21st Century

2000, Today & Tomorrow

The Tech Bubble and attacks of September 11 led to an unstable start to the new millennium. Yet Cretors continued to innovate by introducing new hot dog, caramelizing and pizza equipment while expanding warming cabinet options and topping and dispensing systems. Options and features like the PopIt N’ TopIt, Roc N’ Roll and One Pop were all introduced, allowing buyers to customize machines for their needs. Likewise, the food processing unit continued to grow with Flo-Thru® performing as well as Cretors commercial machines sales. The fifth company president, Andrew G. Cretors, took the helm in 2006. In 2014, Cretors moved to the state-of-the-art 101,000 square foot facility to Wood Dale, IL. Whether looking at the historic poppers or looking into the Innovation Lab, you’ll see that Cretors is a company that innovates and endures, responding to and adapting to cultural change, economic shifts and the global landscape.

2000

Cretors’ line of supplies continued to grow alongside its equipment innovations, expanding to include essentials like popcorn salt and bags, caramel mix, neutral glaze, non-stick spray, and Cheese Paste. The offerings also grew to support operators more broadly, with cotton candy sugar and a full range of equipment cleaners—further reinforcing Cretors’ role as a one-stop solution for concession success.

2004

BIG! was a reality television show on the Discovery Channel in 2004, where teams were challenged to build oversized versions of everyday items in just five days. The first project was a blender that produced a 500-gallon smoothie. The second was a popcorn machine inspired by the Cretors antique-style Profiteer. The finished machine stood 22 feet tall—four times the size of the original.To lend credibility, producers asked Charlie Cretors to evaluate the build. When a fabricator was dismissed on day two, Charlie joined the team—unbeknownst to them, he was a trained engineer who had grown up in the Cretors shop and had designed the original Profiteer machine.

After the show wrapped, Cretors Co. purchased the oversized machine and brought it to their Chicago facility. This accomplishment is later recognized by the Guiness Book of World Records for being the world’s largest popcorn machine.

2005

A new line of Hot Dog Grills and Bun Warmers is introduced, expanding the Cretors equipment line and continuing our tradition of innovation in concession equipment.

2009

The Mach 5 marks a milestone in Cretors history as the 5th generation model of the revolutionary Earn More machine, first introduced in 1924. It is also the first to be developed using our newly adopted Lean Manufacturing process, signaling a new era of efficiency for the company.

2012

Our equipment line continues to expand with the addition of Humidified Food Warmers, broadening our offerings and meeting the evolving needs of our customers.Poppi, the industry’s first compact, industrial countertop hot air popper, is designed and patented—bringing in a new era of oil-free popping technology for gourmet popcorn shops and other retail locations seeking a high-performance, oil-free solution. A few years later, the innovation continued with the debut of Poppi XL, offering increased capacity and efficiency for high-volume environments.

2014

C. Cretors & Company relocates its headquarters and manufacturing operations from Chicago to Wood Dale, Illinois under the guidance of fifth generation company president Andrew Cretors. This move was driven by the company's need for a larger, purpose-built facility to accommodate its growing and evolving production requirements. The new, space offered greater manufacturing efficiency, and expanded R&D capabilities.The patented Double Feature machine is added to the product line—an industry first that combines a popper and caramelizer in one unit. With fewer machines to operate and clean, customers can produce high-quality caramel popcorn faster and with less effort, all within a compact footprint—boosting productivity and profit.

2020

In response to the evolving needs of businesses during the COVID-19 pandemic, Cretors designs, manufactures, and launches the Safety Solutions product line. This engineered collection includes Mobile Floor Shields, Hand Sanitizer Floor and Counter Stands, and Hand Wipe Floor Stands—all developed to help provide an added layer of protection for employees and customers. These durable, easy-to-use solutions support safer environments in retail, foodservice, and public spaces during a time of heightened health and safety awareness.

2021

The UV-C Sanitizing Chamber is added to the Safety Solutions product line, offering a fast, effective way to sanitize a wide range of items using powerful UV-C light technology. Designed for efficiency and ease of use, the chamber provides 360-degree surface sanitization in just 1 to 5 minutes—helping reduce the spread of germs on high-touch objects such as tools, electronics, and personal items. This addition reinforces Cretors’ commitment to supporting cleaner, safer environments across industries.

2024 and Beyond

Cretors is leading the way in sustainability by embracing renewable energy and smarter design. Our Wood Dale manufacturing facility is powered in part by solar panels, helping reduce our carbon footprint and support a cleaner environment. At the same time, we continue to innovate by developing products that are more energy-efficient than ever—integrating technologies like Infrared and Induction heating in select poppers and introducing eco-friendly popcorn bags. These advancements help our customers operate more sustainably without sacrificing the high performance they expect. It’s all part of our commitment to building a brighter, greener future—one pop at a time.Coming to the Chicago Area? Contact Us About a Tour of our Museum!