Pop Science

Although nearly every one has popped corn at home – do you know why popcorn pops and what affects the process? Delve into the captivating world of popcorn innovation and technology. Here, we uncover the secrets behind the perfect pop and explore the science that drives our passion for this beloved snack.

1. Popcorn

Popcorn is the original puffed snack food. Popcorn is also probably the oldest snack food in the in the world. Corn has been a basic food source to the inhabitants of the American continents for over 5000 years. Today corn has been cultivated so long that the original wild grains are hard to find. All the Native Americans ate corn as a staple part of their diet. They also ate popcorn. The oldest positively identified corn popper's date from about 300 AD along the Northeast coast of Peru. The oldest written record is from the Spaniards in 1650. The early American pioneers cultivated popcorn along with dent corn. Dent corn was used for cornbread, and popcorn was used as a breakfast cereal.

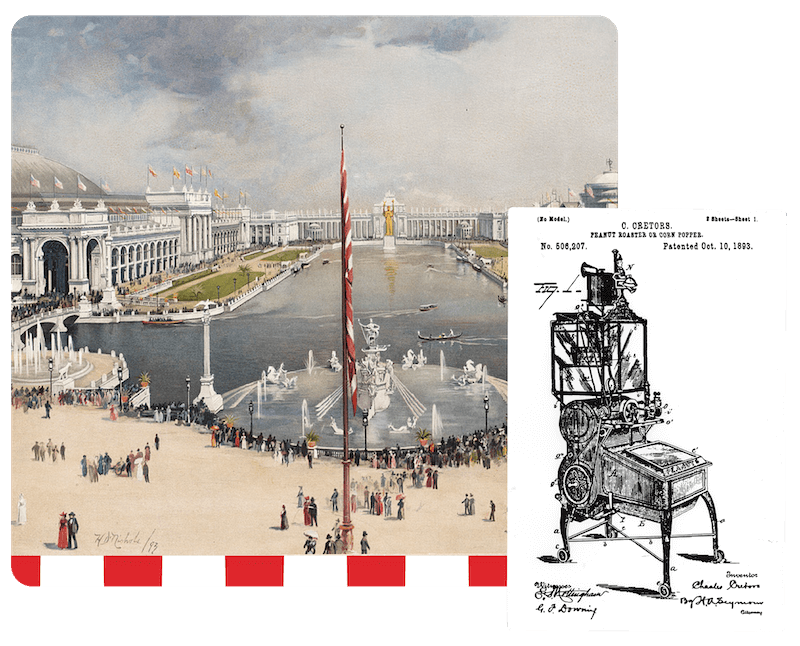

The 1893 Colombian exposition in Chicago was a turning point for popcorn. Cracker Jack was introduced and became the first commercially successful snack food based on popcorn. It was at this same exposition that Charles Cretors introduced his mobile, gasoline fired popcorn machine. This new machine improved the production method so much that popcorn was able to move out of the home kitchen and into the concession stand and retail store.

2. Popcorn and Other Corn

Many people will ask the question. “What do you do to make corn Pop? The quick reply is “Heat it”. What many do not realize is that popcorn is a particular kind of corn, only popcorn will pop. Other types of corn can be puffed with special mechanical processes but only Popcorn or a close relative can be popped on its own without special equipment.

There are basically six kinds of corn which fall into two basic groups, Soft or Hard. This is determined by the amount of hard or soft starch contained in the corn kernel. The most common soft corn is Dent corn and it has many uses. From making baby powder, Tortillas, breakfast cereal, and cattle feed to making ethanol used to improve the performance of gasoline. Other soft corns are Sweet Corn and Flour Corn.

Popcorn falls into the category of Hard, or Flint corns. The multi colored corn seen in the fall of the year and often called Indian Corn is a flint corn.

Popcorn is a form of flint corn and is different from dent and other soft commercial corn varieties in two ways. The first is that it is almost entirely hard starch. The second is that it has a very hard pericarp that permits the internal pressure and temperature to rise high enough to pop.

Hybrids

Hybrid Selection

Within the popcorn family there are many different hybrids. These are obtained by cross breeding different strains of popcorn to emphasize specific characteristics in the corn after it is popped. Some of these characteristics are:

- kernel size

- kernel shape

- kernel texture

There are several varieties or Hybrids of commercially available popcorn, the primary groups are, yellow and white. There are also some novelty products such as black and miniature popcorn.

Yellow popcorn is the most common used for commercial applications. The kernels are rounded in shape and have a medium brown color. Within this group there are several options available to the buyer. Kernel sizes are defined as small, medium, and large. The shape of the popped kernel is also affected by hybrid. Most corn when it pops takes on an irregular shape and is referred to as “Flake” popcorn. Other hybrids take on a more rounded shape and are referred to as “Ball”, or “Mushroom” corn.

White popcorn is a small white grain that looks similar to a grain of rice. Some specific hybrids use the names “Baby Rice”, “Japanese Hull-less”, or “White Hull-less”. The pericarp on this grain is thinner than other hybrids and when popped is not as noticeable when eaten. When this hybrid is popped the popped kernels are very white, small in size and very tender. Due the fact that this hybrid is so tender and fragile it is used almost exclusively in the home. When used in commercial applications there is excessive breakage.

Flake corn is used in most applications and Mushroom is used for the production of sugar coated or caramel corn. The Mushroom kernels have fewer small protrusions to break off in the relatively rough handling that occurs in the caramel coating process.

“Hull-less” Popcorn

3. From the field to the Customer

Popcorn growing areas

Raw popcorn processing

Moisture content

After the corn is sorted and cleaned it is dried to the proper moisture to provide the maximum expansion of the corn. Once corn has been dried it may be stored almost indefinitely as long as the moisture level is not permitted change. Kernels of popcorn over 4000 years old found in the caves in New Mexico were popped in a test.

Corn that has been stored for a period of time will have more uniform moisture than recently picked and process corn. The result is easier operation and tuning up of automatic machinery.

Popcorn is usually delivered to the user with moisture content between 13.5% and 14.5%. The actual moisture content will depend on the hybrid and what the corn processor determines will give the popcorn maximum expansion when popped. Old corn is not a concern as long as the corn has been stored in such a way that the correct moisture is maintained.

The correct moisture for popcorn is in the range of 13-½ to 14-½ %. The correct moisture will vary from hybrid to hybrid and is not a given value. Too little moisture and the kernel will not pop, too much and it may become moldy in storage before it is used.

Most processors utilize computerized color sorters. Virtually each kernel is inspected by an optical system that identifies any discolored kernels, weed seeds, stones, etc., and removes them with a jet of air. The clean corn is then sent to packaging.

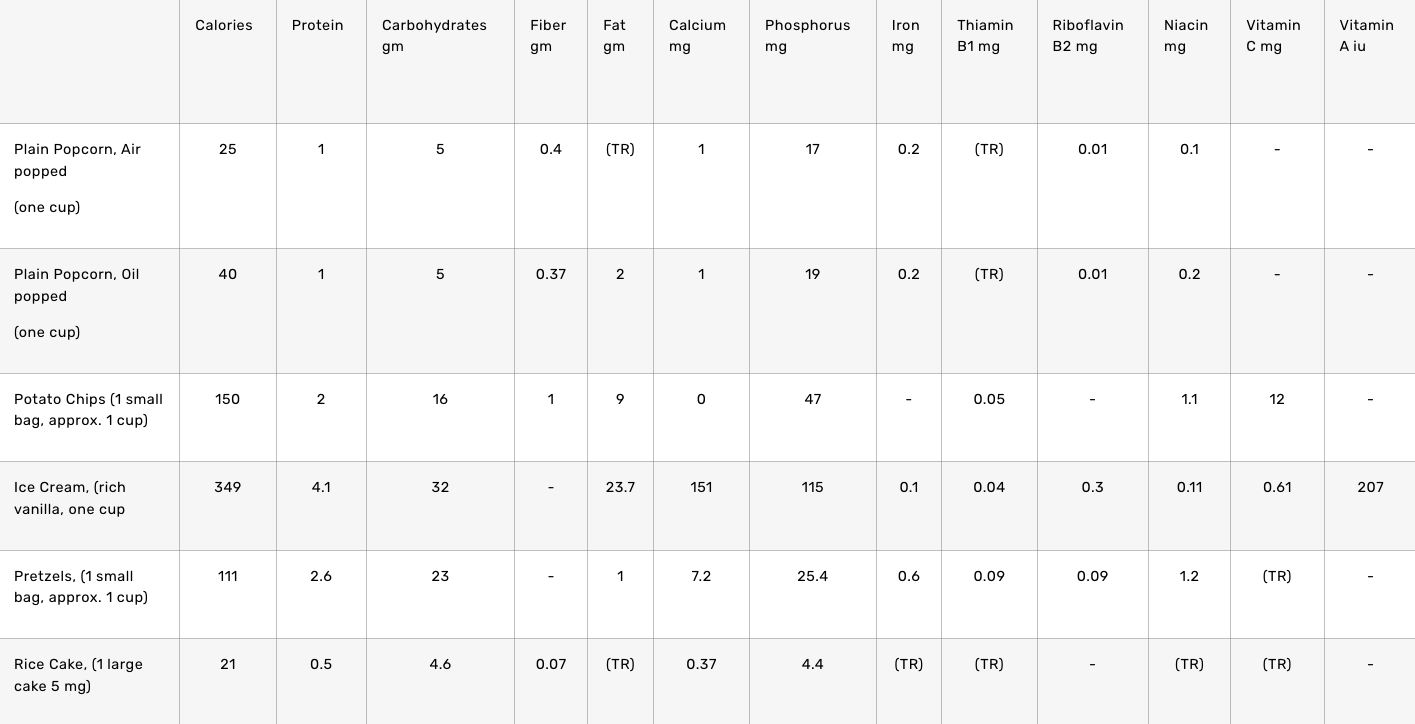

4. Nutrition

| Calories | Protein | Carbohydrates gm | Fiber gm

| Fat gm | Calcium mg | Phosphorus mg | Iron mg | Thiamin B1 mg | Riboflavin B2 mg | Niacin mg | Vitamin C mg | Vitamin A iu |

Plain Popcorn, Air popped (one cup) | 25 | 1 | 5 | 0.4 | (TR) | 1 | 17 | 0.2 | (TR) | 0.01 | 0.1 | - | - |

Plain Popcorn, Oil popped (one cup) | 40 | 1 | 5 | 0.37 | 2 | 1 | 19 | 0.2 | (TR) | 0.01 | 0.2 | - | - |

Potato Chips (1 small bag, approx. 1 cup) | 150 | 2 | 16 | 1 | 9 | 0 | 47 | - | 0.05 | - | 1.1 | 12 | - |

Ice Cream, (rich vanilla, one cup | 349 | 4.1 | 32 | - | 23.7 | 151 | 115 | 0.1 | 0.04 | 0.3 | 0.11 | 0.61 | 207 |

Pretzels, (1 small bag, approx. 1 cup) | 111 | 2.6 | 23 | - | 1 | 7.2 | 25.4 | 0.6 | 0.09 | 0.09 | 1.2 | (TR) | - |

Rice Cake, (1 large cake 5 mg) | 21 | 0.5 | 4.6 | 0.07 | (TR) | 0.37 | 4.4 | (TR) | (TR) | - | (TR) | (TR) | - |

5. Why popcorn pops

Although nearly every one has popped corn at home in a pot the average person knows very little about the why popcorn pops and what affects the process.

Unlike most commercial snack foods the puffing process occurs naturally in popcorn. The popcorn kernel has a very hard hull or pericarp that is capable of withstanding an internal pressure of 135 PSI (9.1 atmospheres). The starch in a popcorn kernel is a hard starch containing about 14% moisture. When a kernel of popcorn is heated the pressure and temperature in the kernel rise, the starch cooks or gelatinizes. At about 135 PSI (9.1 atmospheres), the pericarp ruptures and the pressure is released, the water expands to steam and stretches the starch cells to many times their original volume. The stretched starch cells take on a foam structure. As the steam is vented to the atmosphere, the pressure drops to atmospheric pressure. As the pressure drops the temperature also drops. At the lower temperature the starch returns to a solid state but is now in the form of an open-cell foam. This foam structure is what makes popped popcorn crispy.

The actual popping process requires a delicate balance of heat rate and moisture content. If the kernel is heated too quickly the starch at the center of the kernel is not gelatinized and softened. The starch at the outer edge reaches the required temperature and causes the pericarp to rupture but the uncooked starch at the center of the kernel does not expand. The result is a small hard partially popped kernel of corn. If the heat process is too slow the build up of internal pressure cannot keep up with loss of moisture as steam vents from the tip of the kernel. (The pericarp of the kernel is hard and not porous and contains the increasing pressure. The tip of the kernel where it grew from the cob is not pressure tight and will gradually equalize internal pressure with its surroundings).

The balance that must be made is to heat the kernel at a rate that is slow enough to cook the starch to its core. This must be accomplished before internal pressure ruptures the pericarp: but not so slowly that the small amount of moisture available leaks out before the kernel reaches popping temperature and pressure.

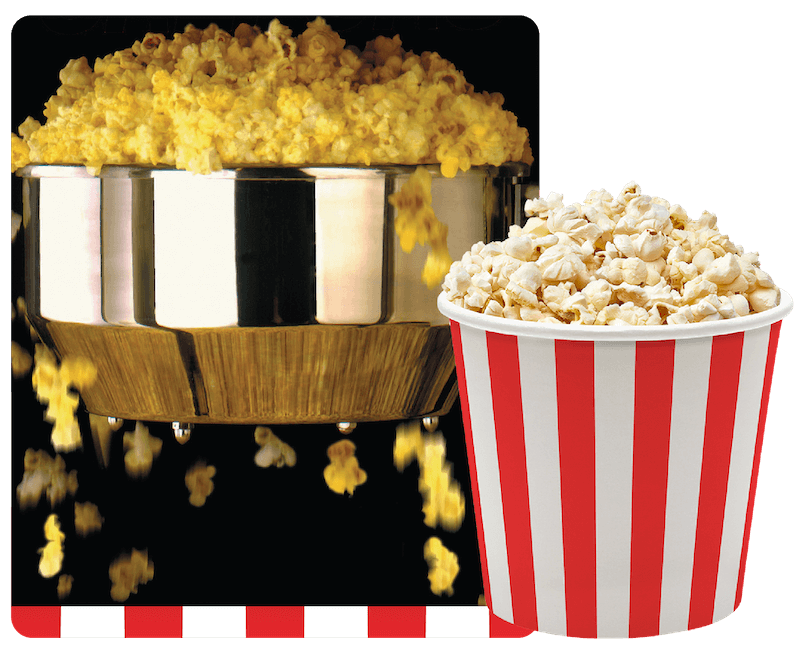

Popcorn Expansion

When a kernel of corn pops there are two primary factors that you should be ii interested in. The first is the expansion of the kernel, or how big it pops. The second is the percentage of kernels that do pop.

Expansion is the amount of growth in volume that the corn goes through in the popping process. In general the more the corn expands the better the product. High expansion corn is desirable for both the consumer and the manufacturer.

From a consumer’s point of view high expansion corn is more tender and has fewer partially popped kernels that are hard to chew.

From a commercial standpoint the expansion can have a direct affect on the profitability of the operation. In concession stands at sporting events and in movie theaters the concession operator buys popcorn by weight and sells it by volume (full box or bag). High expansion translates directly to increased profitability. Each percentage point of increased expansion is a reduction in raw material cost.

In snack food plants where the end product is packaged and sold by weight the financial reason to favor high expansion is not as pronounced, however it does exist. The customer usually equates high expansion corn with high quality. For the manufacturer high expansion will create a physically larger bag for the same weight and may be considered a better value by the customer. High expansion corn also usually indicates a low percentage of un-popped kernels or scrap. In this case corn is not only purchased by weight but it is also sold by weight. Lower scrap reduces raw material costs.

If the expansion of the corn supplied to a snack food manufacturer is not consistent it creates two problems. The first is that when customers do not find a consistent product they do not search for a particular brand. The second is that when the expansion is low, a pre-printed bag filled to the correct weight will not appear full to the consumer.

To measure popcorn expansion, commercial corn processors and large popcorn consumers use the Metric Weight Volume Tester (MWVT) to determine the potential expansion of a batch of popcorn. The MWVT is the official measuring instrument of the Popcorn Institute, an organization that represents many of the popcorn processors in the United States. (The MWVT is manufactured by C. Cretors & Co. of Wood Dale, Illinois)

The MWVT was originally developed for the popcorn processors own use in their corn processing plants. Before hybrid grains became common, moisture and growing conditions were the primary factors affecting the expansion of the popcorn. The popcorn processor would take a small sample from a large bin of freshly harvested corn and test it with the MWVT and record the result. The processor would then begin to dry small samples of the corn, testing the expansion as the process continued. As the corn was dried from normal harvesting moisture the expansion would increase. When the tests indicated the expansion was beginning to decrease the processor knew at what moisture content the whole batch of corn should be dried to in order to get the maximum expansion from the corn.

The MWVT consists of a batch type oil popper with a calibrated cylinder into which the popped corn falls. This cylinder is calibrated to define the expansion of the corn in cubic centimeters of popped corn per gram of raw popcorn input.

The MWVT is equipped with instrumentation that permits accurate means of measuring the temperature and energy consumption of the popper and the expansion of the popped corn. This instrumentation makes it possible to duplicate results from one machine to another and provides a means of comparing different batches and hybrids of corn.

In the typical snack food plant a quick method for determining the effectiveness of the adjustments made to the popcorn machine and the efficiency of operation is needed.

The MWVT is used primarily as a guide to the future performance of popcorn when it is popped. Once corn is popped another method of measurement is needed. The most useful is bulk density. While the MWVT defined to volume of popcorn produced as a function of the amount of raw corn that was popped the bulk density of the final product gives an indication of the effectiveness of the popping process itself.

In addition to moisture content, corn hybrid and physical condition also affect the expansion of popcorn. Cracks and abrasion on the outside of the kernels will reduce popping expansion.

Dry pop Process

When popcorn is popped without the use of oil the process is referred to as dry popping. This process is found in the home, commercial, and in industrial situations.

The first hot air poppers were wire baskets containing a small amount of popcorn that were held over a fire. The baskets were shaken rapidly to agitate the corn and keep it from burning. Today commercial versions of this process use a motorized rotating wire drum over an open flame or electric heat elements.

Today dry-popped or hot-air popped corn is used mainly in the Snack Food industry. Many specialty popcorn shops also use dry popcorn as a base for the many products they make and sell. Industrial hot air poppers are continuous automatic machines that have many applications. The industrial hot air corn popper is essentially a continuous-feed, fluidized-bed oven. While it is primarily a popcorn machine, it is also used to puff third generation snacks, roast peanuts and it will process any type of snack that requires precise temperature and time control and where a continuous process is needed. The dry pop machine used in specialty shops uses a rotating wire screen to simulate the shaken wire basket used in the 1800’s.

Dry popping Machinery

When popcorn is popped without the use of oil the process is referred to as dry popping. This process is found in the home, commercial, and in industrial situations.

The first hot air poppers were wire baskets containing a small amount of popcorn that were held over a fire. The baskets were shaken rapidly to agitate the corn and keep it from burning. Today commercial versions of this process use a motorized rotating wire drum over an open flame or electric heat elements.

Today dry-popped or hot-air popped corn is used mainly in the Snack Food industry. Many specialty popcorn shops also use dry popcorn as a base for the many products they make and sell. Industrial hot air poppers are continuous automatic machines that have many applications. The industrial hot air corn popper is essentially a continuous-feed, fluidized-bed oven. While it is primarily a popcorn machine, it is also used to puff third generation snacks, roast peanuts and it will process any type of snack that requires precise temperature and time control and where a continuous process is needed. The dry pop machine used in specialty shops uses a rotating wire screen to simulate the shaken wire basket used in the 1800’s.

Batch Dry Poppers

Batch poppers are made with a rotating wire drum with a fine mash that supports raw popcorn over an open flame or electric heat element. A coarse wire mesh shaped like a helix is fitted inside the drum. The mesh in the helix is coarse enough that the raw popcorn grain will fall through and popped corn will not. When the corn sitting on the fine mesh outer screen pops it becomes too large to fall through the inner screen. The shape of the inner screen feeds the popped corn out of the drum as the drum rotates.

Batch Popper operation

Continuous Dry Poppers

Hot air poppers are continuous automatic machines that have many applications. The commercial hot air corn popper is essentially a continuous feed fluidized bed oven. While it is primarily a popcorn machine, it is also used to puff third generation snacks, roast peanuts and will process any type of snack that requires precise temperature and time control and where a continuous process is needed.

The basic design of a hot air popcorn machine incorporates a horizontal rotating perforated metal cylinder. Popcorn or any other product to be processed is introduced into one end of the cylinder. Heated air is forced up through the perforations in the cylinder with enough pressure to fluidize the raw popcorn lying on the bottom surface of the drum. The high velocity of the air agitates the corn and provides for very rapid and uniform heat transfer.

Popcorn kernels are a raw grain, the only processing they have been exposed to is that of drying to the correct moisture and cleaning to remove undersized kernels. The variables of a natural product require that the popcorn machine operator be able to adjust the machine to compensate for variation in kernel size, shape, hybrid and moisture content. In addition to accommodating the variables in the raw grain control of the process variables permit the operator to modify the shape of the finished popcorn kernel and the scrap rate.

Microwave

With the advent of Microwave ovens in the kitchen popcorn moved from a covered pot on the stove to a prepackaged bag in the oven. Today it is the predominant method of popping corn in the home. Due to the cost of the machinery and the cost of operation Microwave has not been developed in industrial markets.

Popcorn has been around for a long time and it should not be underestimated. It is perceived as a healthy snack and can be flavored to appeal to many consumer groups. There are a number of options on how popcorn can be produced and marketed. Popcorn only requires a little imagination to develop a marketing plan and the discipline to deliver a high quality product to take advantage of the potential sales.

Oil pop

Oil popping (Machinery)

Machinery for popping corn in oil is primarily used in the concession industry and as such the range of equipment available is generally sized for a concession stand. The standard poppers are gas or electrically heated. Individual poppers suitable for industrial applications are typically 40 Pounds (18 Kg) per hour production.

As volume requirements increase production lines made up of one or more banks of the large oil poppers are set up on a conveyor belt. Typically six poppers are set side by side and one operator to adds corn, oil and salt to the machines. Operating on a typical three-four minute cycle the operators will dump and empty and refill a popper every thirty seconds. Corn is usually fed by hand with sized measuring cups.

Oil may be added to the kettle in several different ways. Oil is circulated from a large central oil storage tank to volumetric measuring points above each popper. When it is time to recharge a popper the dry ingredients are added to the kettle and the oil measure is emptied into the kettle. Another approach is to have a timed metering pump at each popper. This pump may draw oil from a manifold that circulates from a central tank or from individual 50 Pound (22.68Kg) pails. In another option the pumps are immersed in the pails themselves and are equipped with a heat element to melt oil that is solid at room temperature.

Popping Oils

The oil in the oil popping process serves two purposes. The first is to transfer the heat from the bottom of the popping pan or kettle to the popcorn kernels. The second is to add flavor to the finished product.

In general terms any shelf stabile oil that will tolerate the high temperature of the popping process can be used. When choosing popping oil several factors should be considered.

- Melting point. If the melting point is above body temperature, 98.60F (370C), the finished product will leave a waxy coating on the inside of the mouth of the consumer. Popcorn is often consumed in conjunction with cold drinks, which will accentuate this waxy sensation and create an undesirable product.

- Usability. Melting point also affects usability. Liquid oils are generally easier to handle. Coconut oil has a melt point of 76OF (24OC) and can solidify in pipes in cold weather climates. Some Canola oil varieties will separate into liquid and solid phases at lower temperatures.

- Clean ability. The temperature in a popping kettle usually exceeds 4500F. This temperature will carbonize and burn oil left in the kettle. Some oils are more inclined to creating a carbon buildup the kettles. This has a direct relationship to the amount of polyunsaturated fat in the oil. The oil chosen should not smoke at the popping temperature. Oils heated to their smoke points begin to decompose and will have a very short shelf life.

Popular popping oils in the United States

- Coconut

- Corn

- Peanut (Potential allergy problems should be considered)

- Sunflower

- High Oleic Sunflower

- Canola

- Soybean

- Commercially sold oil blends

Salted (Savory) Corn

Sugar (Sweet) Corn

Sweet Popcorn is very similar to Salted corn in its process. In this process the amount of corn and oil placed in the popping kettle is reduced and an amount of sugar equal to approximately 75% of the normal corn is added. On the surface this appears to be a very simple change. The situation is complicated by the fact that the corn requires a kettle temperature of 4500F (2500C) to pop the corn. Sugar begins to burn at a much lower temperature, about 3200F (1600C). The temperature of the popping kettle must be reduced to reduce burning of the sugar and as a result the time for the popping cycle is increased and the output of the kettle reduced from its capacity for salted corn.

Sugar corn is usually a white product and is the result of popping oil that has no color added to it and is popped with white sugar.

In the actual process there are two approaches to the addition of the sugar to the kettle. Sugar can be added with the corn and oil. The result is a slightly browned product near the end of the popping cycle. The sugar may also be added just as the corn begins to pop. This will give a whiter corn but the sugar on the corn may not melt completely and have a flat grainy appearance. The choice of method will depend on the local market.

In the actual operation of the kettle the operator must be more attentive when making sugar corn due to the fact that the kettle must be emptied as soon as the corn is done popping. If it is allowed to remain in the kettle the sugar will begin to burn. Even with careful operation the sugar will create leave an accumulation of carbon on the surface of the kettle. A kettle making sugar corn will require more frequent cleaning than a kettle making salted corn.

Kettle Corn

Sweet Popcorn is very similar to Salted corn in its process. In this process the amount of corn and oil placed in the popping kettle is reduced and an amount of sugar equal to approximately 75% of the normal corn is added. On the surface this appears to be a very simple change. The situation is complicated by the fact that the corn requires a kettle temperature of 4500F (2500C) to pop the corn. Sugar begins to burn at a much lower temperature, about 3200F (1600C). The temperature of the popping kettle must be reduced to reduce burning of the sugar and as a result the time for the popping cycle is increased and the output of the kettle reduced from its capacity for salted corn.

Sugar corn is usually a white product and is the result of popping oil that has no color added to it and is popped with white sugar.

In the actual process there are two approaches to the addition of the sugar to the kettle. Sugar can be added with the corn and oil. The result is a slightly browned product near the end of the popping cycle. The sugar may also be added just as the corn begins to pop. This will give a whiter corn but the sugar on the corn may not melt completely and have a flat grainy appearance. The choice of method will depend on the local market.

In the actual operation of the kettle the operator must be more attentive when making sugar corn due to the fact that the kettle must be emptied as soon as the corn is done popping. If it is allowed to remain in the kettle the sugar will begin to burn. Even with careful operation the sugar will create leave an accumulation of carbon on the surface of the kettle. A kettle making sugar corn will require more frequent cleaning than a kettle making salted corn.

6. Popping Methods